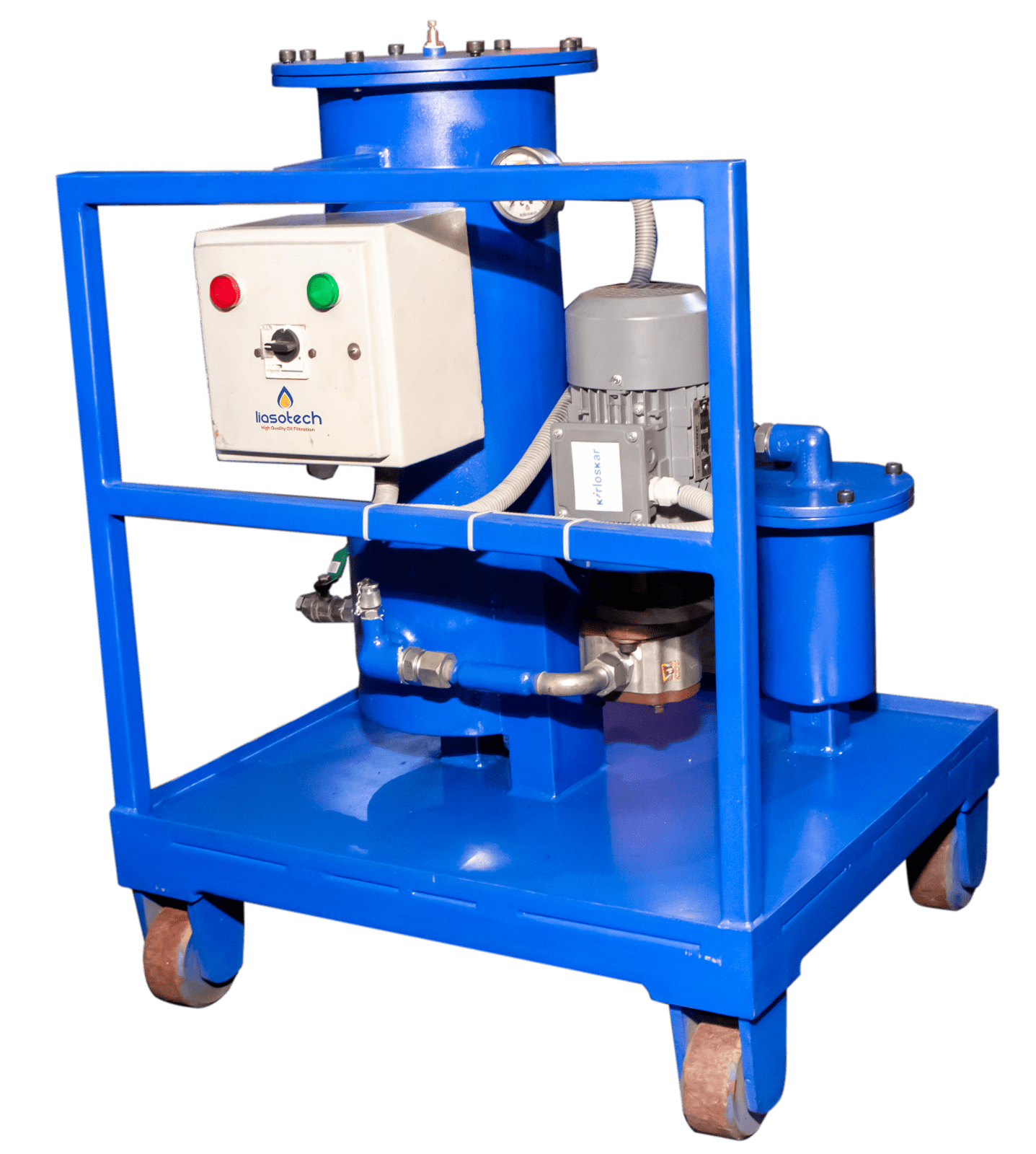

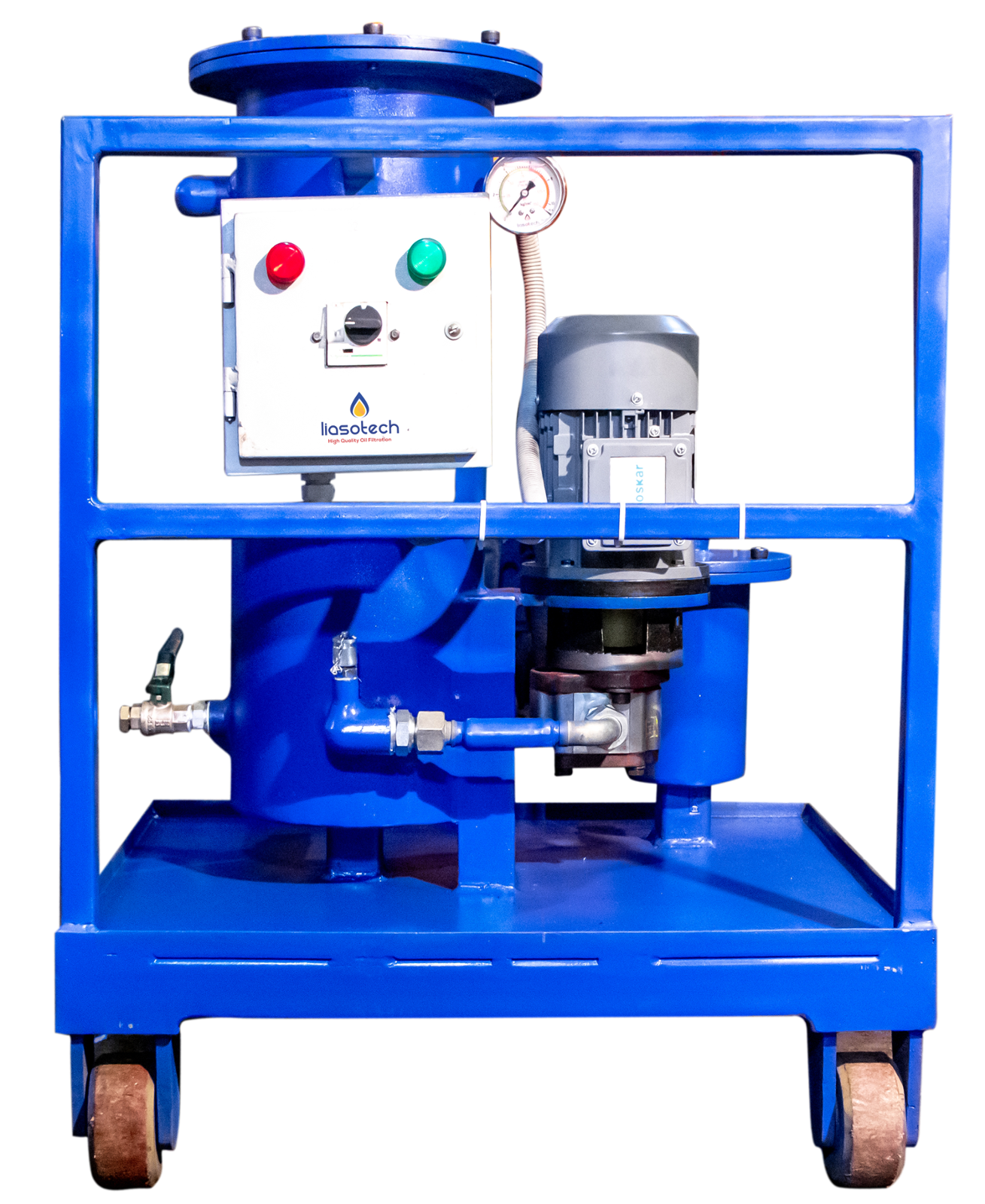

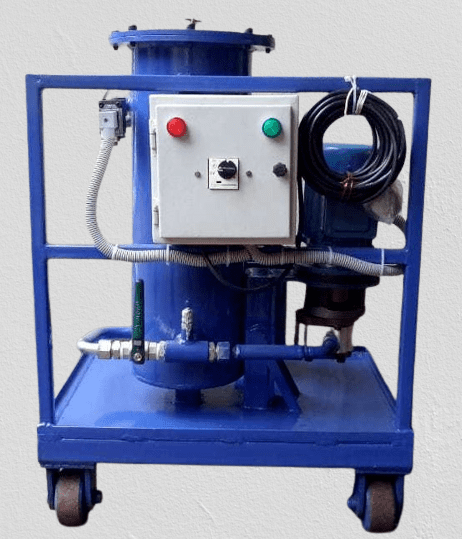

A leading Cold Rolling Mill company achieved remarkable results with our cutting-edge Hydraulic Oil Filtration Machines

A company producing high-precision steel strips, had been using ELC machines for oil filtration but was not meeting NAS Class 3 cleanliness requirements. After procuring three Hydraulic Oil Filtration Machines from Liasotech, their oil cleanliness levels improved significantly, ranging between NAS Class 0 and NAS Class 1. This resulted in better control over breakdowns in their plant. Liasotech demonstrated exceptional professionalism and expertise throughout the trials and the clients were highly satisfied with the results.

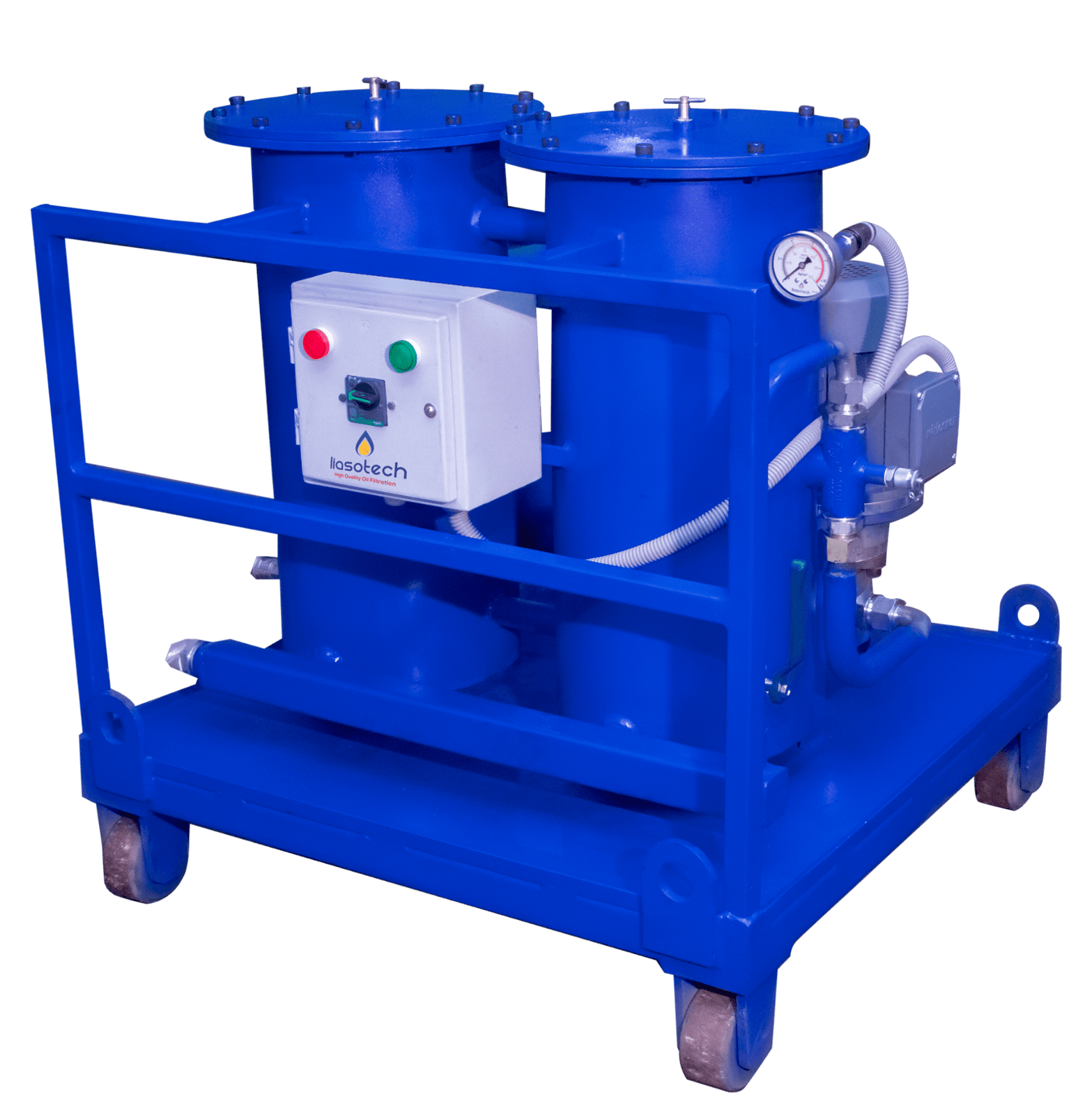

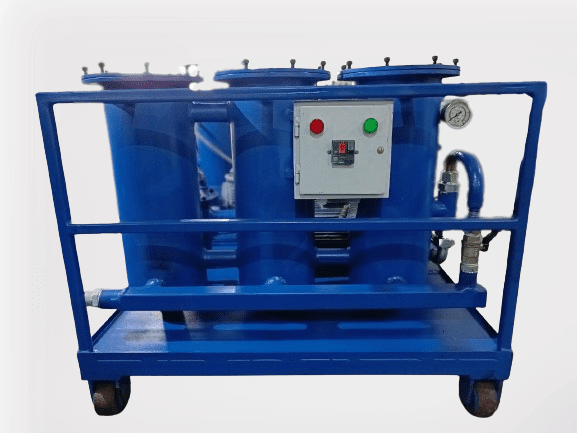

Implementing Liasotech Oil Filtration System has been a game-changer for a renowned Chemical Manufacturing Company

Frequent oil changes and machine breakdowns were causing excessive downtime and high maintenance costs for a Chemical manufacturing company. After commissioning Liasotech Oil Filtration System, their machines started running better than ever. The filtration system effectively removed contaminants, significantly extending the life of the oil. This led to a reduction in oil consumption and disposal costs, saving overall costs. Moreover, the improved oil quality resulted in enhanced performance and longevity of the machinery. They experienced fewer breakdowns, translating to less downtime and more consistent production schedules.

By implementing Liasotech's Hydraulic Filtration System in a leading Steel Plant, the plant achieved an impressive oil cleanliness level of NAS 3 within a short span of time

Turning Challenges into Success, Liasotech achieved a remarkable cleanliness level within a very short period in a leading Steel Plant in India

Liasotech's Filtration Technology Boosts Production and helps to save maintenance costs at the Automobile & Ancillaries Plant

Liasotech’s filtration system improves machinery efficiency and product quality by effectively eliminating water contaminants and carbon emissions are also reduced

A leader in the plastic injection molding industry, seeking to improve the efficiency and longevity of their machinery. Operating advanced injection molding machines such as UBE 830T, Mitsubishi 650T, Haitian 1080T, and Ferromatik 775T, 550T, they faced carbon and water contamination challenges, impacting machine performance and product quality. Liasotech’s filtration system was seamlessly installed into the existing setup with minimal disruption. The system's design ensured efficient filtration, targeting carbon and water contaminants effectively. The implementation process was smooth, and the Liasotech team provided exceptional support and service, aligning with their commitment to customer satisfaction.

Liasotech's oil filtration system saved a power generation company 25% in repair costs

Reduced Failures and Increased Production with Liasotech's Advanced Filtration

One of the large steel manufacturers' plants faced frequent equipment failures in their rolling mills due to contaminated lubricating oil. This resulted in costly downtime and reduced production efficiency. They approached us for a suitable solution. Liasotech oil filtration system is specifically designed for high-temperature and high-load applications typical in steel manufacturing. The system included advanced filtration units and thermal stability features. After the commissioning of the oil filtration system, they experienced several benefits like reduction in equipment failures, and improved production efficiency which led to significant cost savings. And most importantly they achieved the oil cleanliness result of NAS 3 from NAS 9 with just 48 hours of filtration. The enhanced reliability of their rolling mills boosted overall output and product quality.

Liasotech's oil filtration solution reduced oil costs and enhanced operational efficiency in one of the leading cement plant

One of the cement plants in India was dealing with high costs associated with oil replacement and disposal due to contamination in their production machinery. Liasotech team assessed the issue thoroughly and to address the issue Liasotech oil filtration system was commissioned which was designed to filter the lubrication oil and thus minimize waste. The implementation led to a significant decrease in the frequency of oil changes, reducing oil consumption by 40%. Additionally, the plant achieved oil cleanliness results of NAS 5 from NAS 11 within just 72 hours of filtration and also achieved substantial cost savings in oil procurement and disposal. The plant officials were delighted and also mentioned they could meet their production targets more effectively, resulting in improved market competitiveness and customer satisfaction.

Liasotech Oil Filtration System has been transformative for a leading mining company

Frequent oil changes and equipment breakdowns were causing downtime and high maintenance expenses in a leading mining company in Odisha. Since commissioning Liasotech Oil Filtration System, the company has seen remarkable improvements in machinery performance. The system effectively removed contaminants, greatly extending the oil's lifespan. This has led to reduced oil consumption and disposal costs, resulting in substantial savings. Additionally, the superior oil quality has enhanced equipment performance and longevity.

1600+

Oil Filtration Systems

30,00,000+

Litres of oil worth active service contracts

100%

Customer Satisfaction