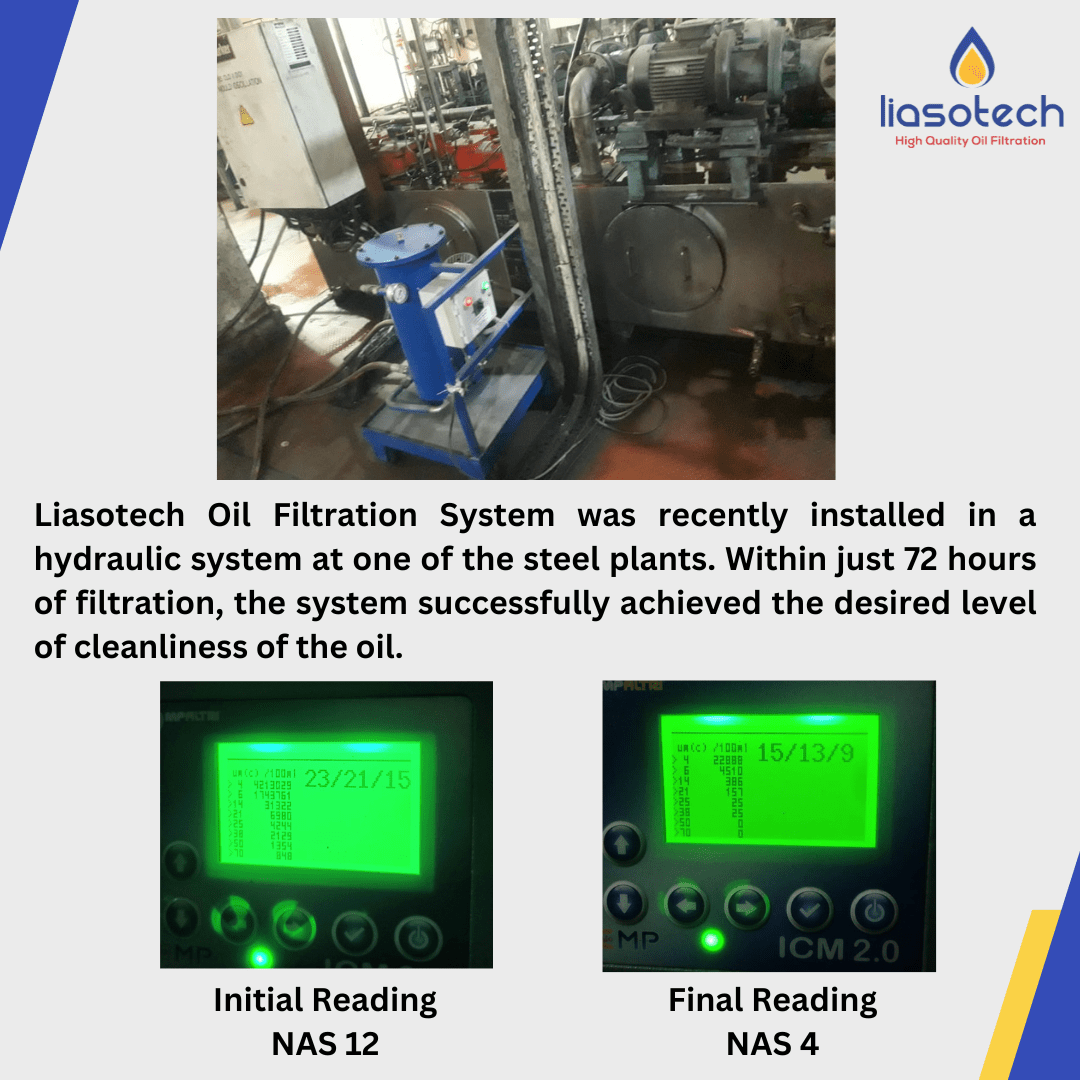

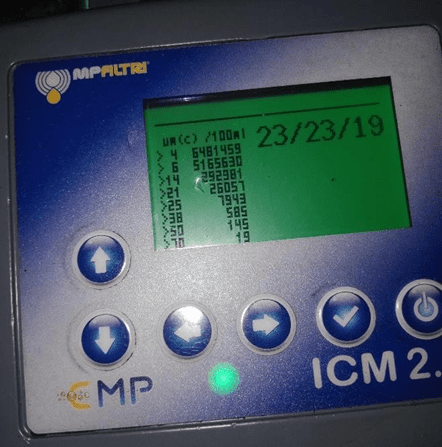

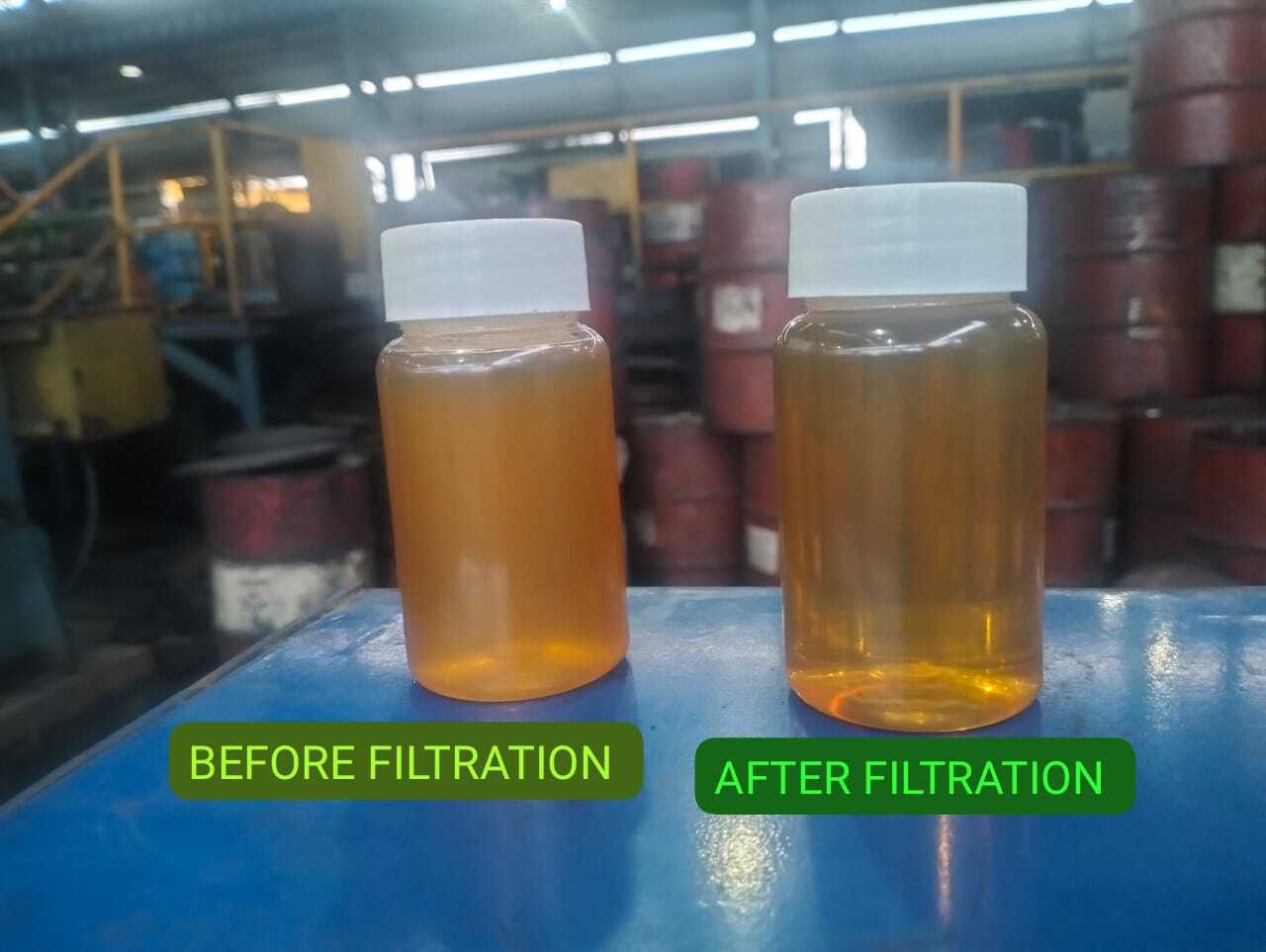

You can see the oil samples and online particle count readings below:

Before Filtration After Filtration Initial Reading Final Reading

Liasotech conducted a successful oil cleaning demonstration at one of our customer's sites in the Plastic industry. This demonstration was crucial for the customer, who had previously faced multiple failures with other filtration companies in their attempts to clean hydraulic oil to the required standards.

Problem

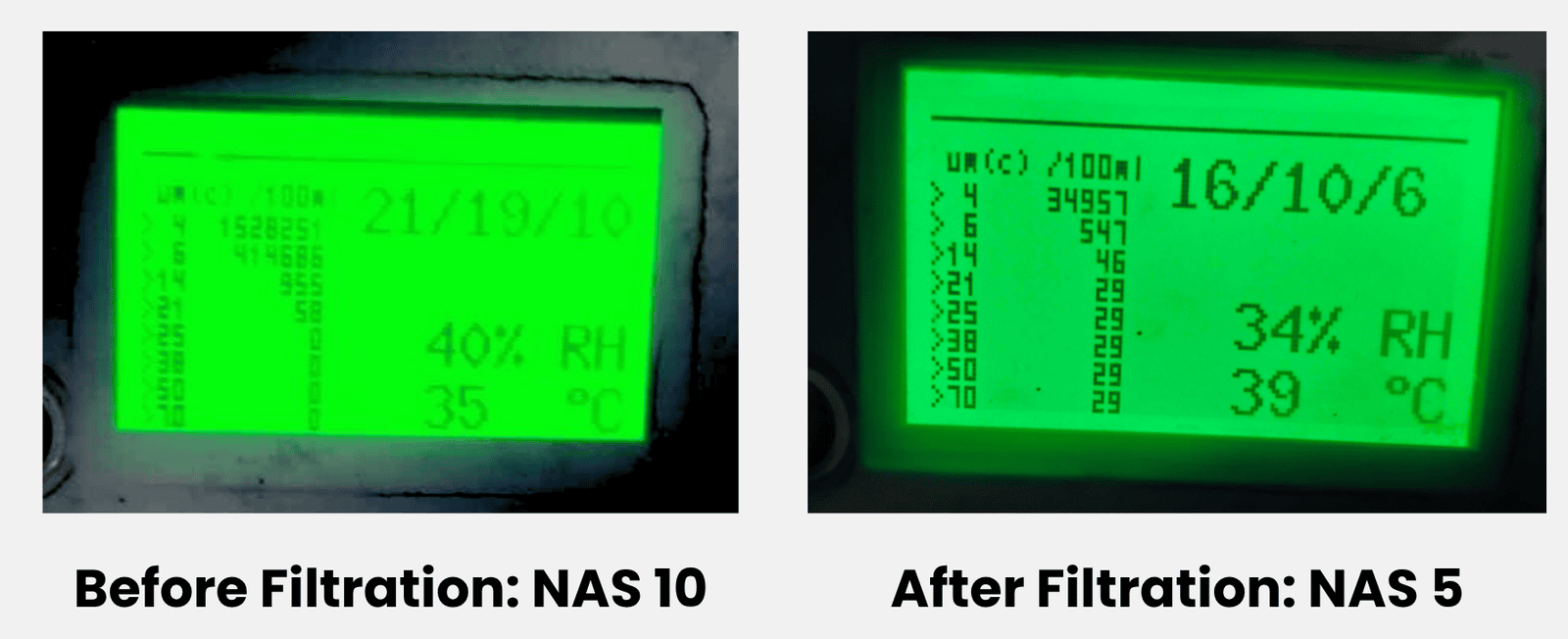

Upon initial assessment, the hydraulic oil was tested and found to have a cleanliness level of NAS >12. This was significantly higher than the system's requirement of NAS 5. The excessive contamination in the hydraulic oil posed a serious risk to the machinery's performance and longevity, necessitating immediate and effective intervention.

Solution

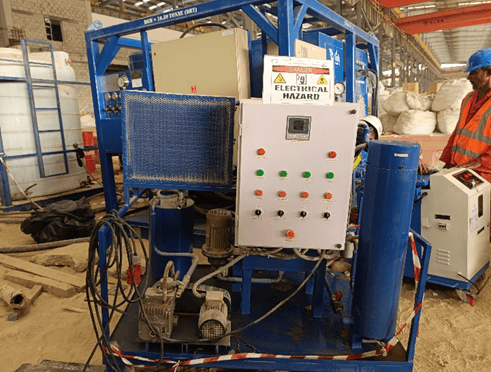

In response to the customer's challenge, Liasotech deployed a skilled service engineer to the site for an initial assessment. Upon testing, it was confirmed that the hydraulic oil's cleanliness level was indeed at NAS 12. To address this, we installed a 12 LPM oil filtration machine equipped with 3-micron filters, all under the supervision of our service engineer. The filtration process commenced and continued non-stop for approximately 48 hours.

Result

The outcome of our intervention was highly successful. The filtration system reduced the oil's cleanliness level from NAS 12 to the desired NAS 5, meeting the stringent requirements of the customer's molding equipment. This significant improvement demonstrated the effectiveness of Liasotech’s technology and expertise in oil filtration.

Benefits

The successful filtration of the hydraulic oil brought multiple benefits to the customer. Firstly, achieving NAS 5 ensured the optimal performance and longevity of their equipment, reducing the risk of breakdowns and maintenance costs. Secondly, the customer, impressed by the results, expressed their interest in placing more orders. This not only solved their immediate problem but also paved the way for a long-term partnership with Liasotech, ensuring sustained equipment efficiency and reliability.

The Problem

An integrated steel plant in Odisha faced a significant challenge in maintaining oil cleanliness within one of its hydraulic systems, which has a 3000 liter tank capacity. Despite operating an ELC filtration machine continuously 24/7, the plant consistently recorded high particle count readings at NAS 10 or higher. Such high contamination levels posed a risk to the efficiency and longevity of the hydraulic system, making it critical to find a more effective solution to ensure system reliability and performance.

The Solution

To address the contamination issue, the plant official decided to replace the ELC filtration machine with our Hydraulic Oil Filtration System (HOFS-16). The HOFS-16 system was equipped with our finest 3-micron absolute filter elements, specifically chosen to eliminate particulate contamination in the hydraulic system effectively.

The Results

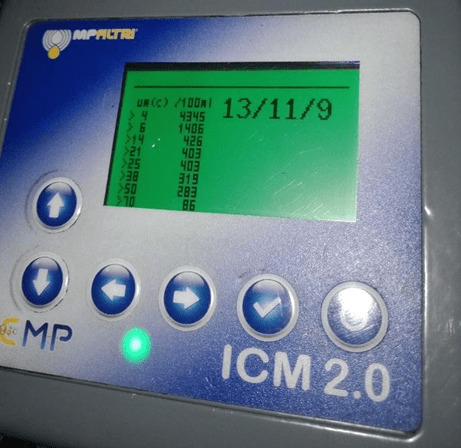

Initial Particle Count Reading - 09:30AM

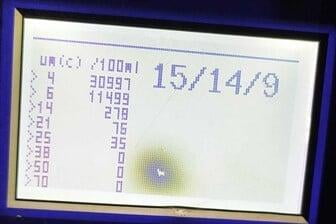

The initial measurement taken at 9:30 am showed a particle count of 20/19/11, equivalent to NAS Class 10. This level of contamination was considerably high and unsuitable for the hydraulic system's optimal performance.

Final Particle Count Reading - 05:30PM

After operating the HOFS-16 filtration system throughout the day, a subsequent particle count reading was taken at 5:30 pm. The reading showed a significantly reduced particle count of 15/14/09, equivalent to NAS Class 5. This indicated a much cleaner state of the hydraulic oil, well within acceptable levels for such systems.

The Benefits:

Implementing the HOFS-16 filtration system brought several advantages:

The significant reduction in particulate contamination improved the hydraulic system's reliability and operational efficiency.

Cleaner oil helps reduce wear and tear on system components, extending their lifespan.

With lower contamination levels, the frequency of maintenance and associated downtime decreases, leading to cost savings.

Maintaining cleaner oil enhances the overall performance of the hydraulic system, contributing to smoother operations and improved productivity for the steel plant.

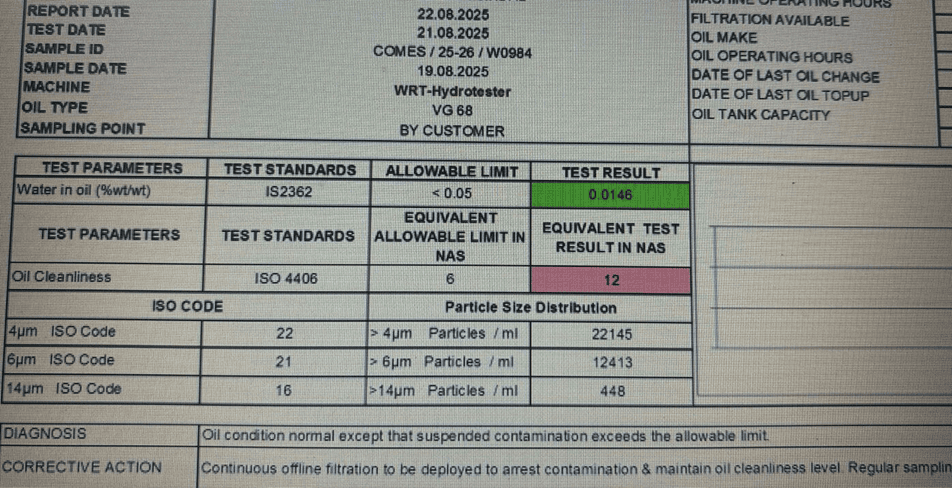

Problem Statement:

A cement plant in Andhra Pradesh had invested on an industrial oil filtration system from another manufacturer. Despite the cost and claimed benefits, they continued to face:

Failure to achieve the target NAS 5 cleanliness level, even after months of use.

Increased maintenance issues with hydraulic and lubrication systems.

Frequent machine downtimes and repairs.

This caused concern among the maintenance and operations teams, who had anticipated improved performance and cost efficiency.

Solution:

After understanding the challenges, we recommended our Advanced Oil Filtration System, designed specifically for critical equipment in dust-prone, high-temperature industries like cement.

Implementation Highlights:

Installed a customized filtration unit compatible with their systems.

Provided on-site technical support for installation and training.

Ran continuous filtration in offline mode, allowing uninterrupted plant operation.

Started regular oil analysis to track progress.

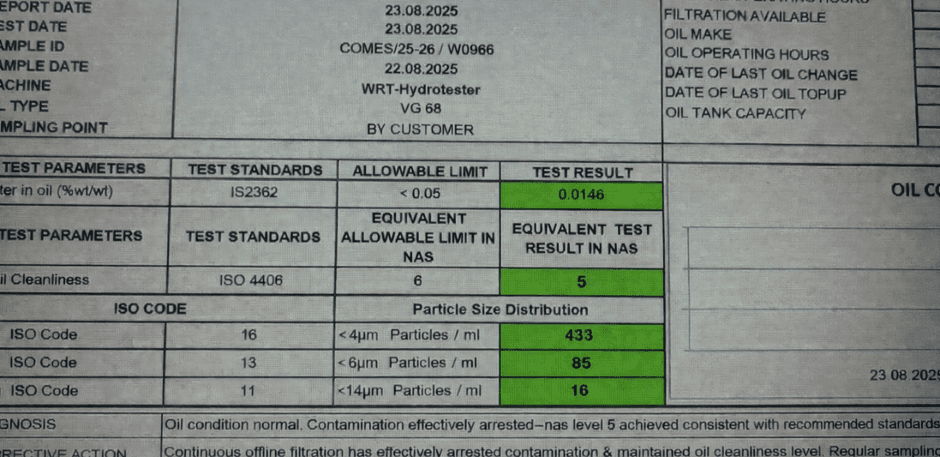

Results

Within a short time frame of 48 hours of continuous filtration, the results were clear:

Oil cleanliness improved from NAS 10 to NAS 5

No replacement of oil was required, which helped them recover losses from their earlier investment.

The maintenance team reported noticeable improvement in equipment reliability and smoother operation.

Benefits:

a) Achieved NAS 5 Cleanliness, improving oil and machine health.

b) Reduced Maintenance Costs: Less component wear and longer oil life.

c) Avoided Costly Oil Replacement.

d)️ Enhanced Machine Uptime in a harsh cement plant environment.

e) Restored Trust in oil filtration solutions after a disappointing experience with a prior vendor.

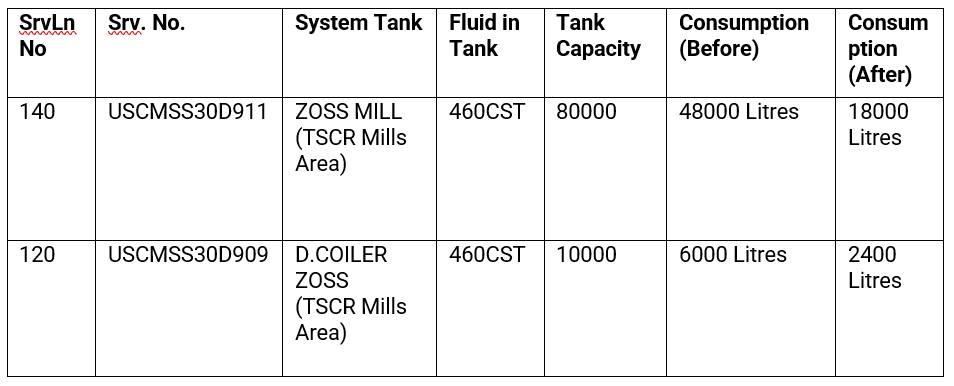

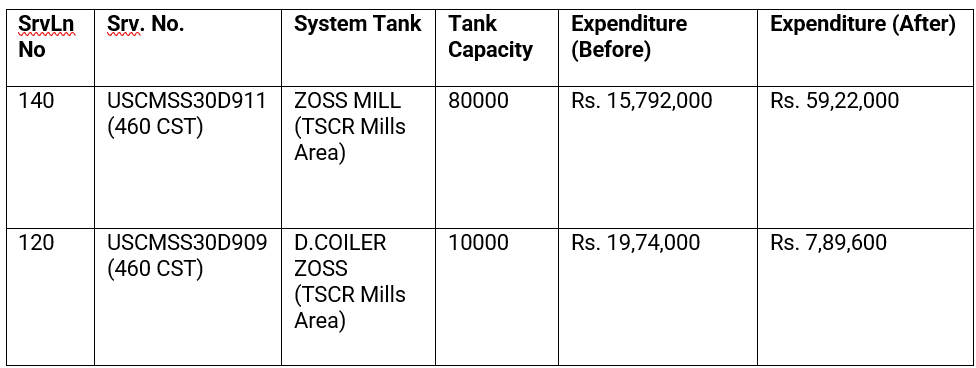

The Problem

A ductile iron pipe manufacturer in West Bengal faced a serious challenge in their plant's hydraulic system.

The plant had already invested in a few number of oil filtration machines. But within just a few months, the Filtration Systems became ineffective, failing to deliver results. Concerned, they began searching for alternatives and that’s when they discovered Liasotech’s hydraulic oil filtration solutions through our website.

When we engaged with their maintenance team and reviewed their oil analysis reports, the root cause became clear:

Oil contamination ranging from NAS 9-12 in various systems, far above acceptable safety limits.

The plant officials explained that:

- Valves in the hydraulic presses were choked frequently.

- Movements became erratic : too slow, too fast, or stuck halfway.

- On the finishing tables, pipes were getting damaged due to delayed valve responses.

Machine cycles were becoming inconsistent, creating production losses and quality concerns

The Solution

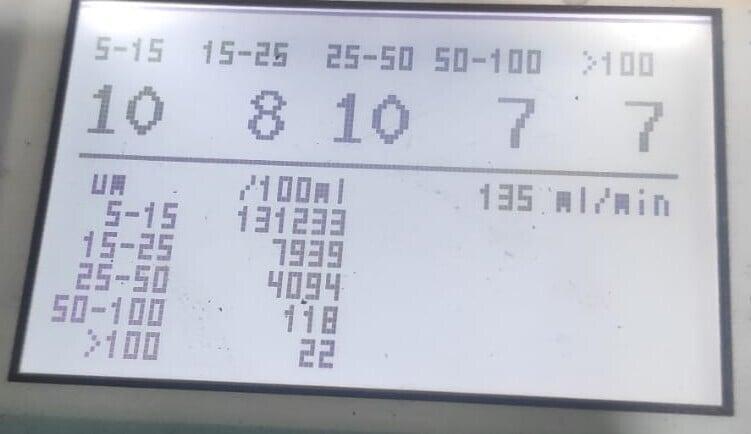

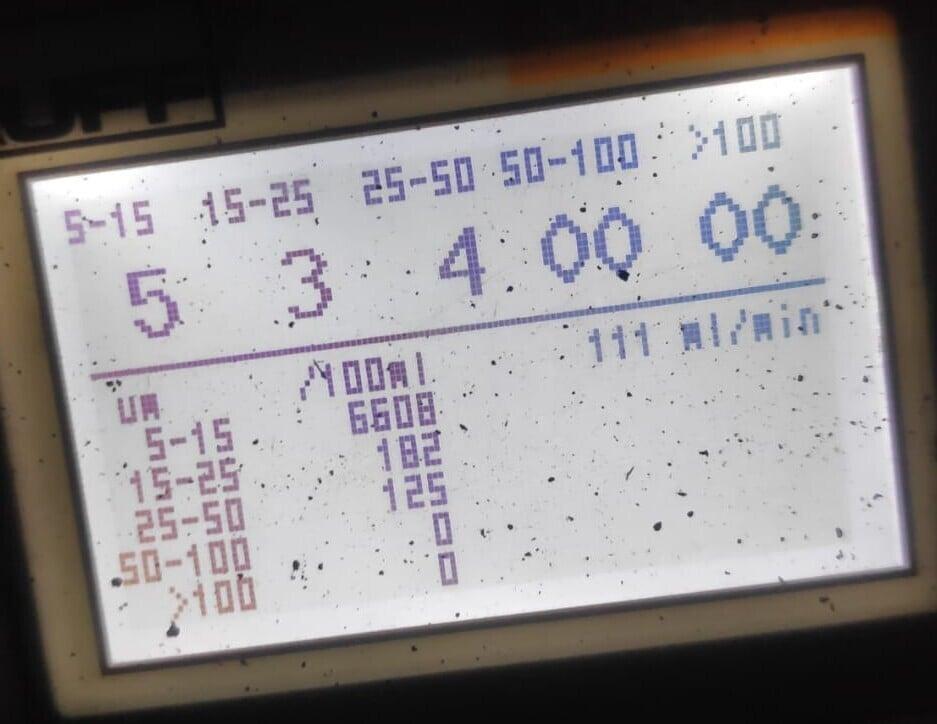

Liasotech Oil Filtration System was then connected to their hydraulic press setup and the first baseline NAS reading was recorded: NAS 10.

We ran continuous offline filtration for 12-14 hours. Once the cycle completed, the new oil report showed: Solid contamination reduced to NAS 5

The Final Verdict:

Problem: Moisture Contamination issue in a Power Generation Company in Gujarat

A leading power plant in Gujarat was facing recurring challenges due to moisture contamination in their hydraulic systems. Despite routine maintenance, they experienced:

Hydraulic failures that delayed production and delivery timelines.

System inefficiencies due to reduced lubrication properties

The operations manager noted,

“Even with regular filtration, we couldn’t remove the dissolved moisture and we kept seeing equipment wear.”

Solution: Deploying Liasotech's Vacuum Dehydrator System (VDS)

While exploring advanced solutions, the team discovered Liasotech’s Vacuum Dehydration System (VDS) :: a system specifically engineered to remove free, emulsified, and dissolved water from hydraulic oils.

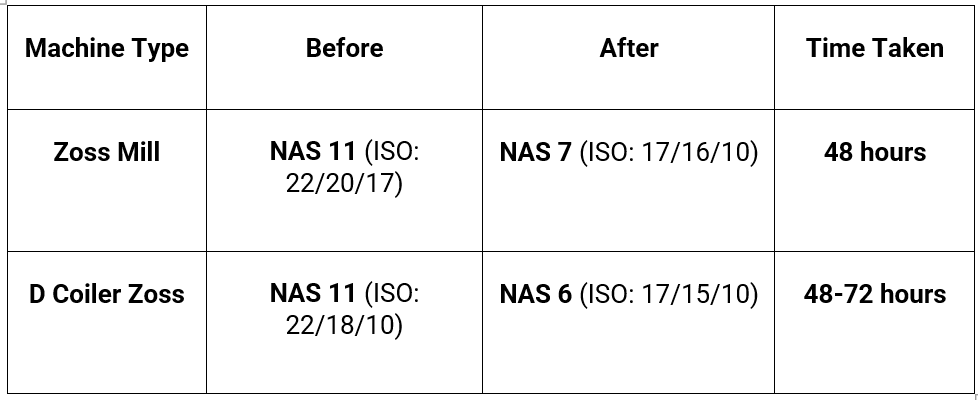

After installation, the results were immediate and measurable for 2 systems:

Mill | Oil Quality before VDS machine installation | VDS Installation Date & Time | VDS Machine Removal Date & Time | Total Time taken for moisture removal | Final Oil Quality |

A | Moisture – 600 PPM | 26.03.25 | 28.03.25 | 34 hours | Moisture – 90 PPM |

B | Moisture – 157 PPM | 04.04.25 | 05.04.25 | 18 hours | Moisture – 87 PPM |

In a few weeks:

Oil life extended by 2x, reducing the frequency of oil changes

Maintenance costs reduced by 30%

Reduced production delays and inefficiencies within 2-3 months

Conclusion: The Experience of Owning VDS

The plant now runs with improved uptime, longer-lasting oil, and reduced wear on critical components.

The officials at the plant mentioned "Installing the VDS wasn’t just a technical upgrade, it completely changed how we think about oil maintenance. And honestly, it paid for itself in just three months"

Liasotech VDS isn’t just a filtration system, it’s a solution that helps plants control costs, improve reliability, and protect their bottom line.

If you’re facing similar challenges, don’t wait for things to escalate, invest in a cost-effective solution before it’s too late, Contact us on 7643993545 today!This contamination led to excessive wear on bearings and gear teeth, causing oil seals to break frequently and resulting in severe oil leakages. The frequent breakdown of seals and leakages forced the plant to top up large amounts of fresh oil, increasing the consumption of Gear Oil.

The system continuously removes fine particles, metal debris, and moisture from the gear oil, ensuring it stays clean and within optimal operating conditions.

By maintaining oil cleanliness, the system prevents abrasive wear that breaks oil seals and causes leakages.

Engineered for dusty and high-load environments, Liasotech’s filtration solution operates continuously without interrupting production.

Result

After implementing Liasotech’s Gear Oil Filtration System, the steel plant experienced:

A dramatic drop in unexpected gearbox failures and unscheduled breakdowns.

Significantly fewer oil leakages and seal breakages, extending the life of oil seals.

Substantial savings on oil consumption costs due to reduced oil top-ups.

- Improved gearbox performance, with overheating and friction issues largely eliminated.

- A shift from emergency repairs to planned, predictive maintenance, boosting overall reliability and productivity.

Key Takeaway

A prominent automotive parts manufacturer in Maharashtra, supplying parts to various OEMs relied on high-capital CNC machining lines for precision components. These lines are the backbone of their production and demand uninterrupted performance to meet tight delivery schedules and maintain product quality.

Frequent unplanned stoppages of critical machining lines.

Rapid degradation of key components such as bearings, spindles etc.

Fine metal particles generated during machining were not being removed effectively by inline filters.

Fresh lube oil consumption was rising 20% above normal levels, adding to operational costs.

These issues posed a serious threat to their high-value capex machinery, risking expensive repairs, unscheduled downtime, and loss of production hours.

Continuously remove fine solid particles down to 3 microns.

Extend oil life by maintaining consistent cleanliness and moisture control.

• (NAS) cleanliness: NAS 11 to NAS 5.

The NAS 5 cleanliness level was achieved after filtering 1,000 litres of contaminated oil for 10 hours.

- Oil Change Frequency: From every 4 - 12 months

- Unplanned Downtime: Reduced by 70%

- Annual Savings Achieved:

- Fresh oil cost savings- 50%

- Downtime cost savings: 45%

Key Benefits Delivered

- Protected high-value capex machinery from wear, rust, and unplanned failures.

- Improved oil life by 3x, reducing waste and environmental impact.

- Reduced maintenance interventions, freeing manpower for more productive tasks.

- Enhanced overall production reliability, safeguarding delivery timelines.

Problem:

A chemical and fertilizer manufacturing plant faced major issues with its lube oil due to contamination:

Water ingress & emulsified lube oil: Water levels exceeded 1,000 PPM, causing emulsification.

High particle contamination: Particles lead to wear on bearings. The particle counter machine showed ISO- 21/19/14 or NAS 10.

Frequent oil changes & valve failures: Oil changed every 3–4 months instead of 12, leading to hydraulic system valves failing every 5 months.

Annual loss: Estimated ₹13–15 lakh due to maintenance, oil changes, and downtime.

Solution:

The plant installed 6 nos of Lube Oil Filtration System for removal of particle contamination and 1 no of Vacuum Dehydration System for water removal. Following steps were implemented as follows:

Installing Lube Oil Filtration System to remove particles with β3 ≥ 500 rating.

Vacuum Dehydrator Filtration System to eliminate free and dissolved water.

Regular Filtration: The process began by removing moisture over a 48-hour period, after which dedicated filtration machines were installed and operated for one week.

Oil Monitoring: Oil testing was done on scheduled interval to check moisture and cleanliness levels.

Results (10 Days Later):

- Water Content: Reduced from 1,000+ ppm to <100 ppm.

- Particle Cleanliness: Improved from 21/19/14 (NAS 10) to 16/13/9 (NAS 5)

- Oil Change Frequency: Increased to every 15-16 months

- Valve Failures/Choking : No breakdown in 12 months since it's date of installation.

- Manual Water Drain: Eliminated.

- Annual Savings: ₹9–11 lakh.

Conclusion:

The Moisture contamination reduced from 150PPM operating at an efficiency of 68% to 60PPM and improved the efficiency to 74%. This improvement not only enhances operational reliability but also supports sustainability by reducing energy wastage, extending oil life, and lowering the environmental impact of frequent oil replacements.

Conclusion:

Implementing our industrial oil filtration system significantly improved turbine performance, reduced downtime, and lowered maintenance costs for the company's power plant in Karnataka.Background : Hydraulic Cylinder's failure costs steel plant ₹30 lakhs in replacements

A steel plant’s coke oven department was experiencing repeated machinery challenges. Their critical hydraulic cylinder, essential for operations, had recently been replaced at a cost of ₹30 lakhs due to severe damage. The root cause pointed to oil contamination issues that were disrupting performance and leading to frequent breakdowns.

Issue : Oil contamination spikes to NAS 10 despite ELC system

Despite using an Electrostatic Liquid Cleaning (ELC) machine, the contamination level of their hydraulic oil had reached NAS 9, far above the acceptable standard. This high level of contamination threatened not only the reliability of their machinery but also posed significant risks of costly downtime and equipment damage.

Solution : Hydraulic Oil Filtration System ensures reliable contamination control

After a thorough evaluation, we recommended the installation of our Mechanical Filtration System, designed to deliver superior contamination control and consistent oil cleanliness. Our solution effectively targets both particulate and moisture contamination, ensuring long-term reliability of hydraulic systems.

Result : Oil cleanliness improved from NAS 10 to NAS 4 within 24 hours

The impact was immediate. Within just 24 hours of installation, the oil cleanliness level improved drastically from NAS 9 to NAS 4. This improvement not only restored equipment reliability but also eliminated the risk of further expensive breakdowns.

Conclusion

Background - A Leading Manufacturer Facing Oil Cleanliness Challenges

One of India’s largest and most reputed ductile iron manufacturers was facing a critical challenge with oil contamination. The company had recently invested in a new filtration system, expecting it to deliver the required cleanliness levels for their operations. However, the system could not reduce the contamination beyond NAS 13, which posed significant risks to production efficiency.

Issue - High Contamination Causing Consistent Breakdowns

Despite installing a new filtration system, the company was unable to achieve oil cleanliness beyond NAS 13.This high contamination level was directly responsible for consistent breakdowns in their machinery, leading to downtime, heavy maintenance expenses, and dissatisfaction within their operations team. The situation was impacting productivity and profitability, leaving the company upset with their return on investment.

Solution - Deploying Our Dual Stage OFS System

Result - From NAS 11 to NAS 4 in Just 24 Hours!

Oil cleanliness improved from NAS 13 to NAS 4 in just 24 hour

- The solution eliminated the root cause of frequent breakdowns, enhancing equipment reliability.

- The client’s in-house team was able to set up and operate the machines independently, proving the user-friendly design and robust performance.

- The client was so impressed that they personally reached out to share their success story with us.

Conclusion - Proven Reliability Through Advanced Filtration

Problem

Solution

Upon evaluating the situation, our team recommended implementing the Vacuum Dehydrator Filtration System (VDFS) — a specialized solution designed to remove both solid and liquid contaminants from hydraulic oil.

The VDFS is engineered to:

Achieve water content levels as low as 500 PPM,

Operate efficiently at flow rates between 20 LPM to 100 LPM, and

Reduce solid contamination levels down to NAS 3 standards.

This system not only eliminates existing contamination but also prevents further rust formation by maintaining the oil’s purity and dryness over long operational periods.

Result

After installing our Vacuum Dehydrator Filtration System, the steel plant observed significant improvements:

Water levels in oil reduced to < 200 PPM, within 48 hours

Elimination of rust formation inside machine components

Restoration of machine reliability and efficiency.

Conclusion

Background

A metal manufacturing company in India was facing an alarming rise in hydraulic oil consumption across its production lines. Despite using high-grade HLP-46 and Servo System-68 oils, the company’s machines demanded frequent oil top-ups and replacements, leading to soaring operational costs.

The Challenge

Hydraulic oil forms the lifeline of their heavy machinery—responsible for powering presses, lifts, and forming units. However, the company’s maintenance team noticed:

Oil darkening and losing viscosity within short intervals

Machines running hotter and slower

Increased frequency of breakdowns and component replacements

Each month, hundreds of litres of fresh oil were being procured to maintain system performance. Given the high cost of hydraulic oils, this cycle became financially draining.

The root cause, as later confirmed, was oil contamination, fine particulate matter, moisture, and oxidation sludge continuously degrading the oil and wearing down components.

A Turning Point

The situation began to change when a new Maintenance Head joined the company. Having previously worked in a large steel processing unit, he was familiar with our industrial oil filtration technology and its long-term impact on oil life and machine health.

Recognizing the symptoms, he recommended trying our offline oil filtration system on their two major hydraulic setups, the HLP-46 and Servo System-68 lines.

The Solution

The Results

Within just a few months, the maintenance team observed measurable improvements:

Oil consumption dropped significantly, no longer requiring frequent top-ups or complete drains.

Oil colour and clarity improved, indicating removal of microscopic impurities.

System performance stabilized, with reduced heat generation and smoother operation.

Machine uptime increased, minimizing maintenance-related downtime.

Now, after Liasotech Oil Filtration system was installed, oil contamination level was reduced to NAS 6 in 48 hours!

Quantified Benefits

Reduction in fresh oil purchase by 50–75% within the first few months.

Extended oil life, from months to years in continuous use.

Payback achieved within the first year through savings in oil and reduced breakdowns.

Conclusion

The Problem

The Turning Point

This led to the decision to explore online oil filtration and vacuum dehydration systems to extend oil life and protect hydraulic components.

The Solution

Key steps included:

Installing a portable online oil filtration unit that operated independently of machine downtime.

Conducting a one-time deep cleaning of the hydraulic tank and replacing only critical components.

Establishing a regular oil monitoring schedule to track moisture, particle count, and viscosity.

The Result

Within three months, the company achieved remarkable improvements:

80% reduction in hydraulic failures and unplanned downtime due to contaminated oil.

Oil life extended from 3 months to over 12 months.

Maintenance cost reduced by 40%.

Improved machine performance and product consistency in plastic moulding.

The Challenge

Frequent servo valve choking

Higher operating temperatures

Repeated unplanned maintenance

Increased hydraulic oil consumption

The management decided to explore alternate filtration systems to resolve their problems.

The Turning Point

When Liasotech evaluated the situation, we reviewed the oil reports and machinery conditions. Based on the contamination level (NAS 11) and the nature of their extrusion press operations, we were confident that their issue was not just filtration—it was the lack of an effective offline system capable of removing fine particles.

The Solution

Liasotech installed its Hydraulic Oil Filtration System, allowing continuous cleaning without interrupting production.

Our system targeted:

Ultra-fine particle removal

Restoring oil performance parameters

During this period, the customer performed oil sampling at regular intervals, monitoring the clarity, particle count, and overall oil behavior inside their extrusion press.

The Results

Within 24 hours, the difference was clearly visible—both in the oil samples and in machine performance.

Key outcomes included:

Oil clarity improved drastically, with contamination levels significantly lower than NAS 5

This image below shows the Patch Test Before Filtration & After installing our Filtration system

Noticeable removal of fine particles

Smoother press operation with more stable hydraulic response

Maintenance team reported less valve sticking and fewer alarm events

The oil appearance changed visibly from dull and hazy to clear and bright

Conclusion

A major integrated steel producer in Abu Dhabi was struggling with recurring hydraulic system issues caused by persistent oil contamination. Despite multiple internal efforts, the plant was unable to maintain required NAS cleanliness levels, affecting equipment reliability and maintenance costs.

The Challenge

The steel plant’s hydraulic systems were showing:

High moisture content in oil, leading to oxidation and corrosion

Frequent failure to maintain NAS cleanliness levels, often rising above NAS 10

Ineffective flushing practices, which unintentionally brought more contaminants back into the system

Increased downtime, premature component wear, and rising maintenance expenses

The plant needed a long-term, reliable solution to control moisture and eliminate fine particulate contamination.

Liasotech’s Solution

After a detailed on-site assessment, Liasotech recommended a dual-technology purification approach:

1. Vacuum Dehydration Oil Filtration System

Designed to remove dissolved, emulsified, and free water efficiently from hydraulic oil, ensuring moisture levels remain well below OEM limits.

2. Electrostatic Oil Filtration System

A high-efficiency, depth-charge system that removes ultra-fine particles (sub-micron to 5µm) responsible for varnish, sludge, and oxidation deposits.

This combination targeted both primary root causes: moisture & ultra-fine contamination.

Results Achieved

Within 48 hrs of commissioning, the plant saw measurable improvements:

NAS cleanliness improved from NAS 10 to NAS 5

Moisture content reduced drastically, (1100 ppm to 150 ppm), restoring oil health

The long term benefits of using our advanced Liasotech filtration machines include:

Hydraulic breakdowns reducing significantly

Extended life of pumps, valves, and seals due to cleaner, drier oil

Reduction in oil consumption, as flushing was no longer required

Operators and maintenance teams expressed high satisfaction with both the performance and ease of operation.

Conclusion

Liasotech’s integrated oil purification solution helped the steel plant transition from reactive maintenance to proactive oil management. By eliminating moisture and fine contamination, the plant not only achieved international oil cleanliness standards but also improved productivity, reliability, and cost efficiency.

Problem

A steel and metal processing plant in Howrah was facing severe hydraulic oil contamination in its wire rod department. Despite having a filtration setup in place, oil cleanliness continued to deteriorate.

A detailed investigation revealed that oil was bypassing a valve, allowing it to circulate without passing through the filtration system. This resulted in continuous recirculation of contaminants and accelerated component wear.

The oil was contaminated at a level of NAS 12 with moisture contamination above 2000 ppm.

Such contamination levels posed a high risk to hydraulic pumps, control and servo valves, seals and actuators.

Solution

Liasotech conducted an on-site assessment and identified the root cause of ineffective filtration. To address the issue, a dedicated Liasotech offline oil filtration system was installed.

The system was designed to:

- Prevent unfiltered oil circulation caused by valve bypassing

- Continuously remove solid contaminants from the oil

- Maintain consistent oil cleanliness independent of system operation

Results Achieved

The implementation of the Liasotech's filtration system delivered measurable and immediate improvements in oil cleanliness.

Post-installation oil condition:

Cleanliness Level improved from NAS 12 to NAS 5

Particle contamination reduced from >2000 ppm to below 200 ppm

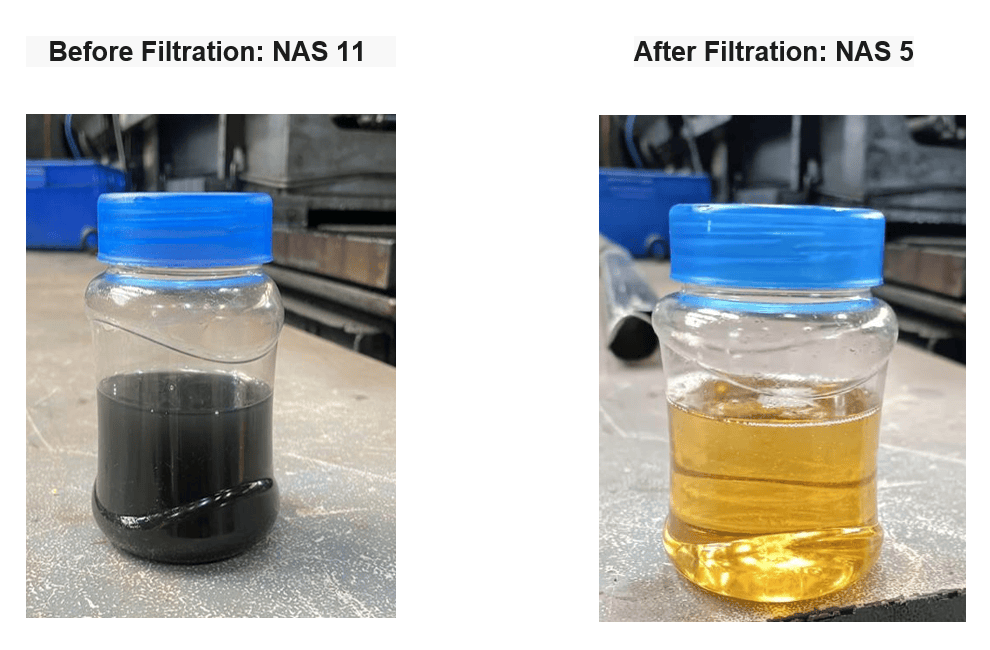

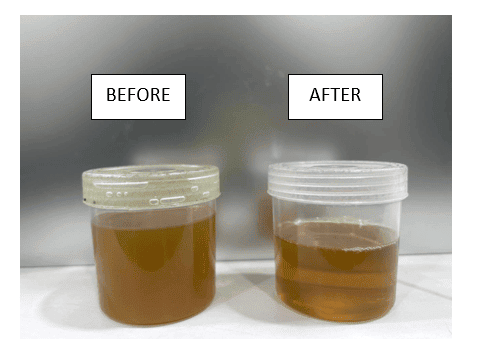

The following before and after snapshot of oil filtration is below:

BEFORE

AFTER

- Improved hydraulic system reliability

- Extended life of oil and critical components

- Reduced maintenance frequency and downtime risk

- Enhanced operational stability in the wire rod mill

Conclusion

Client Profile

The Challenge: Persistent Oil Contamination & Reliability Risks

Despite having routine filtration practices in place, the plant was facing recurring reliability issues linked to oil contamination. Oil analysis revealed that the hydraulic oil cleanliness was consistently at NAS 9, well above the recommended limits for sensitive hydraulic components.

The consequences included:

Increased wear on pumps, valves, and servo components

Reduced efficiency due to degraded oil performance

Higher maintenance intervention frequency

Growing risk of unplanned shutdowns

The operations team observed that conventional filtration methods were unable to control fine contaminants and moisture effectively, leading to unstable oil cleanliness levels.

The Solution: Liasotech Oil Filtration Intervention

After a technical evaluation, Liasotech proposed a specialised oil purification approach focused on restoring and maintaining oil cleanliness without replacing the oil.

The solution involved deploying a Liasotech advanced vacuum dehydration filtration system, designed for continuous cleaning of hydraulic oil, even in large reservoirs.

Key application details:

Oil Type: ISO VG 46

Reservoir Capacity: 10,000 litres

Initial Cleanliness Level: NAS 9

Results Achieved

Within 48 hours (2 days) of system operation:

NAS cleanliness level improved from NAS 9 to NAS 5

Fine particulate contamination was significantly reduced

Oil stability improved, restoring lubrication performance

System noise and temperature fluctuations reduced

The rapid improvement exceeded the plant’s expectations and demonstrated the effectiveness of targeted oil filtration over conventional flushing or frequent oil replacement.

Plant officials highlighted the long-term value of the solution, stating:

“This solution changed our approach to oil maintenance. Instead of reacting to failures, we now focus on controlling contamination. The improvement was quick, and the return on investment was clearly visible.”

Conclusion

This case demonstrates how controlling oil cleanliness rather than replacing oil can dramatically improve system reliability in power generation environments.

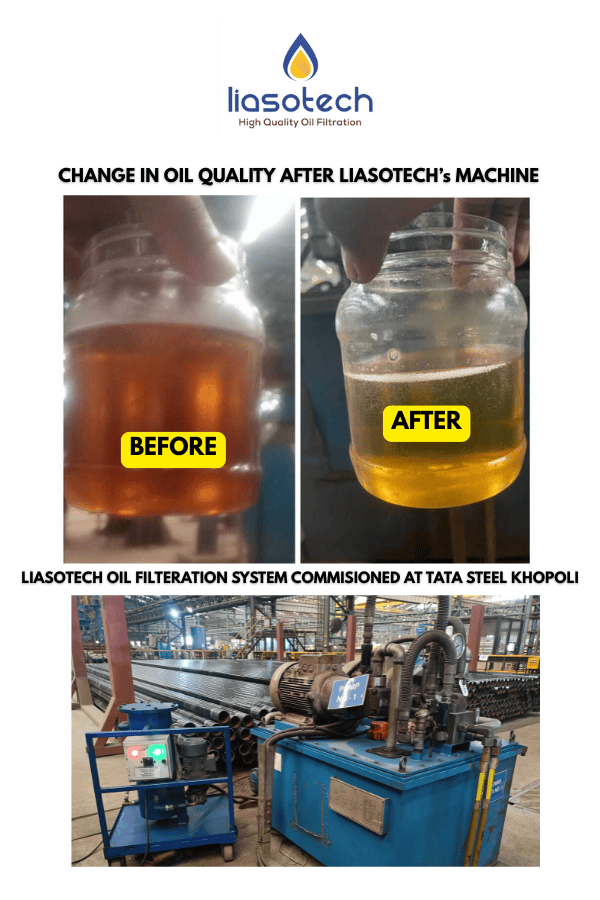

Client Profile

Tata Steel Khopoli is a premier manufacturing facility specializing in high-quality steel products. The case study focuses on their LDP (Long Dia Pipe) division, where round and square steel pipes are manufactured. These production lines rely on heavy-duty hydraulic systems to maintain precision and output speed.

The Challenge: Frequent Valve Breakdowns & Hidden Contamination

Despite regular monitoring, the LDP division faced a critical reliability issue: hydraulic valves were breaking down every two months. These recurring failures caused significant production stoppages and increased maintenance costs.

The Consequences:

Recurring replacement of expensive hydraulic valves.

Unplanned downtime disrupting the pipe manufacturing schedule.

High operational costs due to frequent spares consumption.

The Solution: Liasotech High-Efficiency Oil Filtration System

To address the root cause of the failures, Liasotech implemented a specialized hydraulic oil filtration system designed to revive the oil condition rather than replace it.

The solution featured:

Technology: High-efficiency depth filtration.

Filtration Media: Absolute micron rating of 3 microns to capture ultra-fine particles that cause silting and valve stiction.

Operation: The filtration machine was set up for continuous, 24-hour kidney-loop filtration to progressively clean the reservoir.

Technology: High-efficiency depth filtration.

Filtration Media: Absolute micron rating of 3 microns to capture ultra-fine particles that cause silting and valve stiction.

Operation: The filtration machine was set up for continuous, 24-hour kidney-loop filtration to progressively clean the reservoir.

Results Achieved

The results were immediate and validated over a 2-month observation period:

Rapid Cleanliness Recovery: Within just one week of deploying the oil filtration machine, the oil condition improved drastically.

Superior NAS Levels: The system achieved and sustained NAS Class 2 and 3 across multiple hydraulic power packs—far exceeding the previous baseline of NAS 6-7.

Validation: The machine was kept under observation for two months to ensure the stability of the oil cleanliness under load.

Operational & Business Impact The transition to Liasotech’s high-efficiency filtration yielded significant business returns:

Zero Breakdowns: Valve breakdowns due to oil contamination stopped completely.

Production Continuity: The elimination of hydraulic failures prevented production losses and reduced emergency shutdowns.

Cost Savings: Financial losses associated with frequent valve consumption and maintenance labor were significantly reduced.

Conclusion

The Tata Steel Khopoli project highlights that standard patch testing may not always reveal the true risk to sensitive hydraulic components. By deploying Liasotech’s high-efficiency oil filtration machine with 3-micron depth filters, the plant moved from reactive repairs to proactive contamination control.