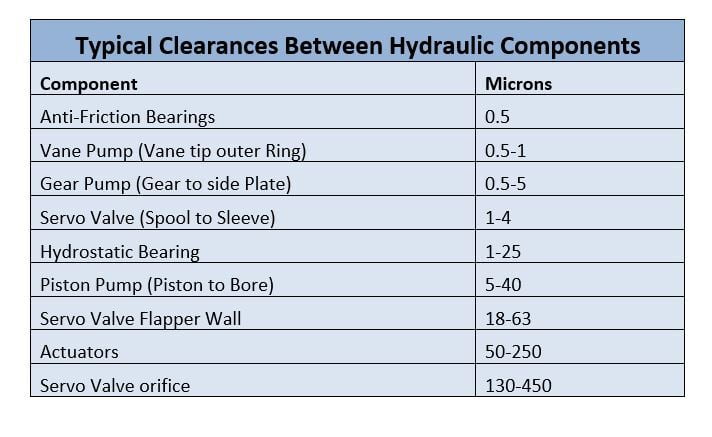

One of the functions of hydraulic oil is to create a lubricating film between two different components of the hydraulic system. This film helps to keep two parts separated and thereby reducing wear. The thickness of this film is important as it should fill the gap between the parts to reduce wear and is dependent on oil viscosity and relative speed of two moving system parts.

If the hydraulic oil is contaminated and there is a contamination particle which is larger than the gap between two system components, it will cause damage to the system. This damage would in turn cause more particles to generate which will further contaminate the system. Thus, it is important to keep particulate contamination size smaller than the clearance size between two moving parts of the system as much as possible.

If we could simply keep the hydraulic oil clean, there would be minimal damage to the system as most of the particles larger than the clearance size would be removed by filtration.

Different types of contaminants

Different types of contaminants are:

· Particle Contaminants like metal particles from Friction and dirt ingress through any gap

· Chemical Contaminants like Moisture, heat, and air.

Contamination in Oil can cause:

· Component Wear

· Decrease in Oil Life

· Orifice Blockage

· Depletion of Additives

Particulate contamination

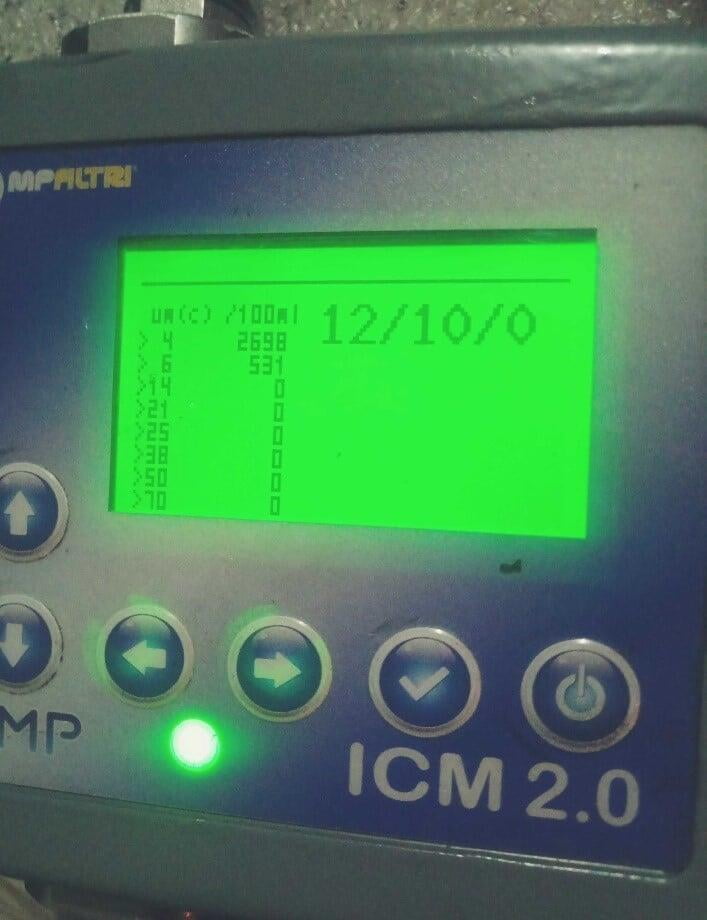

Particle size can be measured only in Microns. Did you know that a human eye can only see a particle which is 40 Microns or higher? We can see a human hair which is 70 microns but not a bacterium which is 2 microns. The particles that mostly damage a hydraulic system are 4 to 14 Microns which is why we measure oil contamination in sizes of 4 Micron, 6 Micron and 14 Micron as per ISO 4406 standard.

Chemical contaminants

Air – Contamination of air in any hydraulic or lubrication system is in the form of dissolved state or free state. The problem is not dissolved air but undissolved air when it passes through the system. This free air under pressure can release a lot of heat in small air bubbles. These air bubbles can cause frothing in oil and damage pumps.

Moisture - Presence of moisture in hydraulic oil has numerous effects on hydraulic system components. The most obvious problems could be formation of rust in tanks and reduction in the lubrication characteristics of oil. Water may also cause oxidation of oil and depletion of additives. In some oils, presence of moisture may also cause formation of Acids, Alcohols and Sludge.

Did you know that just 0.1% or 1000 ppm of water can reduce the life of bearings by 50%? Increase the water content to 1% or 10,000 ppm and bearing life reduces by another 25%.

Heat - Additives present in hydraulic oil can get depleted when exposed to higher heat. Heat may also cause some chemical changes in oil thus altering the property of oil.

Sources of contamination in hydraulic system

Maintenance Contamination – This type of contamination happens during manufacturing or repairing process like for example welding, cutting, grinding, or chipping etc.

Dirty New Oil –New oil is mostly dirty and has not gone through fine filtration process. This new oil is not clean enough for any hydraulic system, let alone for today’s modern high pressure hydraulic systems.

Contamination Ingress –Contamination Ingress can happen from air entering through the breather or any other opening left on the system. If a proper breather is not installed, then it may not prevent moisture from entering the system during humid conditions thereby causing moisture contamination in oil. Particles may also enter through the cylinder rod as no seal can 100% prevent particlulate contamination from cylinder rods. Open the system for maintenance or even connect new hoses and you will have contamination ingress in your system.

System Generated Contamination – Particles that are generated from the system components can also cause harm to the system as they are circulating in oil until removed. They may also generate more particles due to their impact with the system components. If not removed they may cause system failure.

Filter your hydraulic oil

It is now proved that even a fully sealed hydraulic system can see contamination build up. It is therefore important that every hydraulic system should have a way of removing contamination to keep oil clean and system healthy.

Install our compact Liasotech Hydraulic Oil Filtration System and achieve ISO 14/12/09 or NAS 3 oil cleanliness levels. Once you install our system you never have to worry about particulate contamination damaging your system.